High-pressure pumps work on a very simple principle. They work by boosting the pressure of fluids. Liquids with high pressure and high velocity are targeted toward the chocked and blocked surfaces to be cleaned and help to remove dirt and scaling to have cleaning effects and, at the same time, act as pressure maintenance devices for various applications.

Types

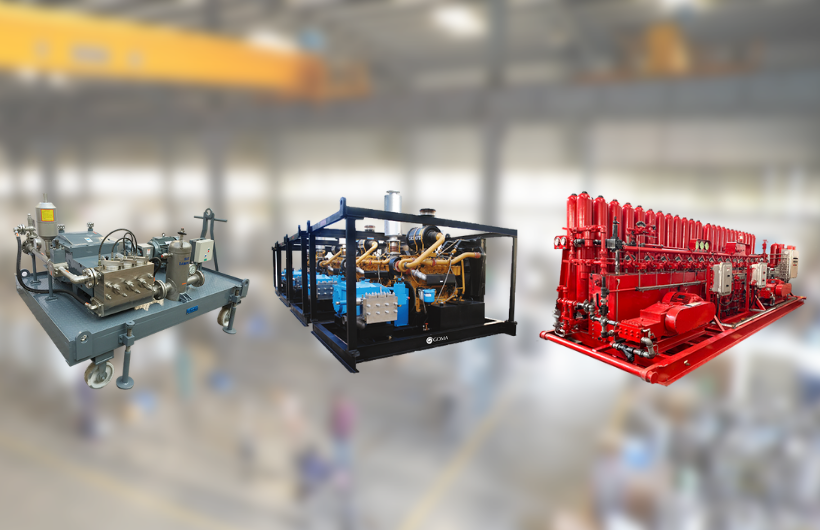

You will find different kinds of high-pressure pumps, all designed for specific applications. Examples include reciprocating, centrifugal, and positive displacement pumps. A reciprocating pump uses a plunger or piston to move liquids. They are often applied where low flow rates and high pressure are needed, like the production of oil & gas. A centrifugal pump uses centrifugal force to carry liquids. We use them in applications where high flow rates are required, like water treatment facilities. On the other hand, a positive displacement pump uses mechanical force to transfer fixed volumes of liquids. It is mostly applied in places where a constant rate of flow is needed, like in chemical processing.

Applications

A good pump must withstand repeated use and more abuse for various applications. These applications may include:

- Pest control and agriculture – Today, agriculture sector depends on these pumps to ensure safety of food. They help to dispense fertilizers, pesticides, and herbicides at exacting pressure and flow rates to have the job done.

- Disinfection services – Demand for disinfection machines is growing every day. Retail stores, schools, and airports depend on disinfection sprayers so as to kill various pathogens in locker rooms, airplanes, buses, bathrooms, and classrooms.

- Commercial Cleaning –The cleaning sector uses these pumps in different applications. They help to clean dockside and restrooms.

Why Use High-Pressure Pumps?

According to experts at Pumpbiz, high-pressure pumps have a long service life and high operating reliability. This is thanks to robust plain bearings and corrosion-resistant components in the hydraulic system. Another reason is that using high-pressure pumps guarantees low costs of operating and optimized efficiencies.

How to Maintain a High-Pressure Pump

To ensure the efficiency and longevity of a high-pressure pump, you will need to offer it maintenance services regularly. With the help of these tips, you can offer regular maintenance to your pump:

- Clean Filters

This involves replacing filters or cleaning them regularly. With this, you can maintain optimal performance as well as prevent clogging

- Lubrication

It is important to keep every moving part well-lubricated. This will not only help to minimize wear but also avoid friction.

- Monitor the Levels of Pressure

Always keep a close eye on the levels of pressure and adjust them accordingly. With this, you will be able to avoid overloading your pump.

- Check out for Leaks

Experts recommend inspecting every valve and connection. This way, you will be able to spot signs of leaks and act immediately when there is a problem.

The bottom line is that high-pressure pumps work the same way our hearts do. They produce a force to ensure liquids flow smoothly. Examples include centrifugal, reciprocating, and positive displacement pumps. To last longer, you will have to ensure you offer them regular maintenance.